One of the most important decisions a mine makes is how it handles its tailings

Dry stacking is quickly becoming the answer when safety, water control, and long-term stability matter.

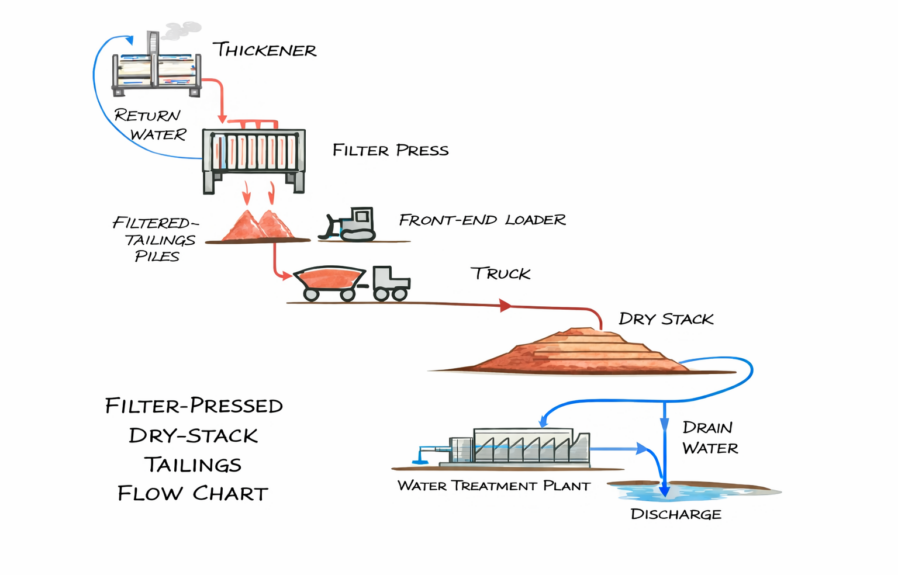

Here’s the flow chart:

1️⃣ Tailings slurry from the processing plant enters the thickener, where the solids concentration is increased.

2️⃣ The thickened slurry is sent to a filter press, which mechanically squeezes out excess water.

3️⃣ Recovered water from the filter press can be returned to the thickener for reuse.

4️⃣ The dewatered tailings leave the press as a solid and form filtered tailings piles.

5️⃣ A front-end loader collects the material and loads it into a truck.

6️⃣ The truck transports the tailings to the dry stack facility.

7️⃣ Any seepage from the dry stack is captured and routed to the water treatment plant.

8️⃣ After treatment, clean water is discharged back to the environment in compliance with regulations.

𝐖𝐡𝐲 𝐝𝐫𝐲 𝐬𝐭𝐚𝐜𝐤𝐢𝐧𝐠?

✅ At high-precipitation sites, controlling water is everything.

✅ Dry stacking reduces the volume of free water stored on site, lowers failure risk, and strengthens environmental performance.

✅ And in regions exposed to large seismic events, dry stacks provide a more stable tailings structure than conventional slurry impoundments.

⭐ This is the kind of engineering choice that quietly protects operations, people, and the environment for decades.

If you work in mining, geotech, or environmental engineering, you’re going to see a lot more of this approach especially in seismic prone site.