Presentation

LASE Industrielle Lasertechnik GmbH is a German company specializing in industrial laser measurement and sensor technology. It’s known internationally for high-precision laser systems and software used across heavy-industry applications. LASE develops and manufactures laser-based measurement systems (1D, 2D, 3D, and multi-layer sensors) and software solutions for precise measurement of profiles, positions, dimensions, and volumes in industrial settings. LASE sells worldwide through its own offices and a network of international distributors. They’ve also developed applications tailored to specific sectors like ports, mining, steel, and logistics.

How LASE laser measurement products transform bulk handling and logistics?

LASE Industrielle Lasertechnik GmbH Technology improves efficiency, automation, and accuracy in bulk material tracking, logistics, mining, ports, and other heavy-industry sectors. The products combine robust laser scanners with advanced software to deliver precise, contactless volume and profile measurement under harsh industrial conditions.

Products

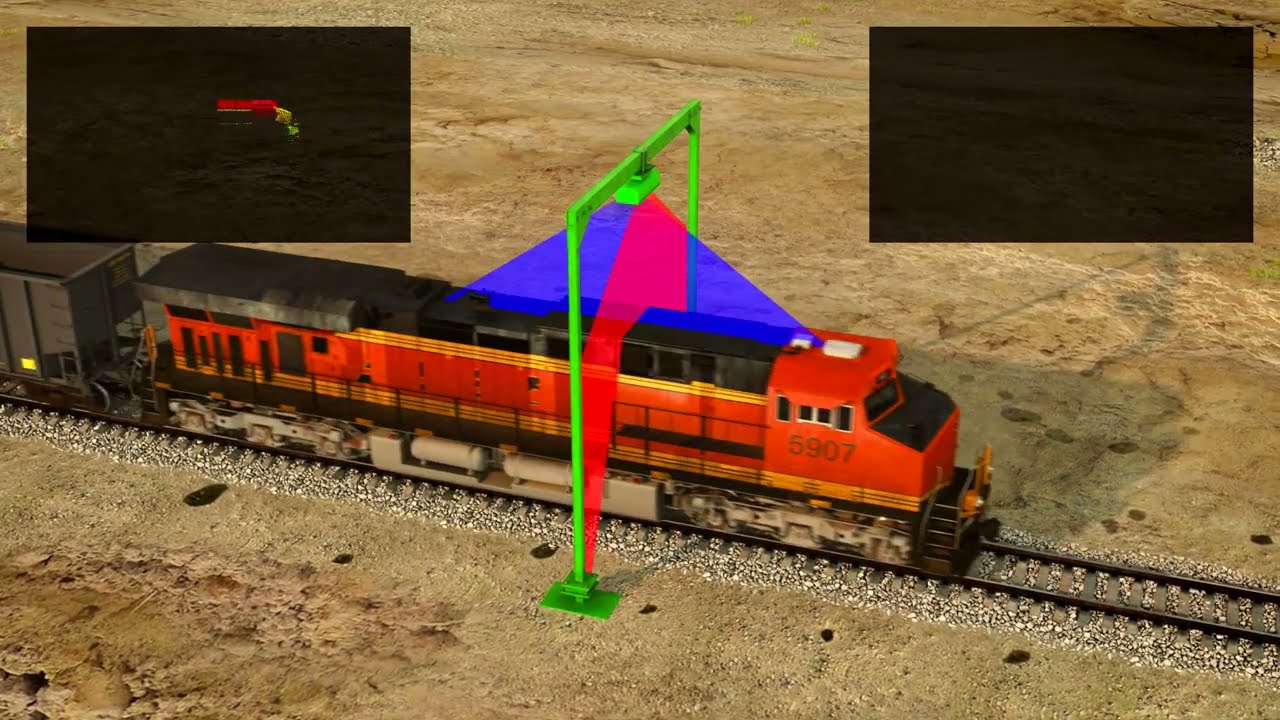

LaseWVM : Wagon Volume Measurement

The LaseWVM system is a non-contact laser solution designed to accurately measure the volume of material loaded in rail wagons, particularly in mining and bulk logistics operations. It works by capturing 3D scans of wagons when empty and when loaded, then calculating the volume based on the difference between both profiles. This enables precise load verification at rail loading stations, supports inventory tracking, billing accuracy, and ensures load consistency. With rapid, repeatable measurements, high precision, and low maintenance requirements, LaseWVM enhances automated workflows, improves logistical planning, and helps reduce quantity-related disputes.

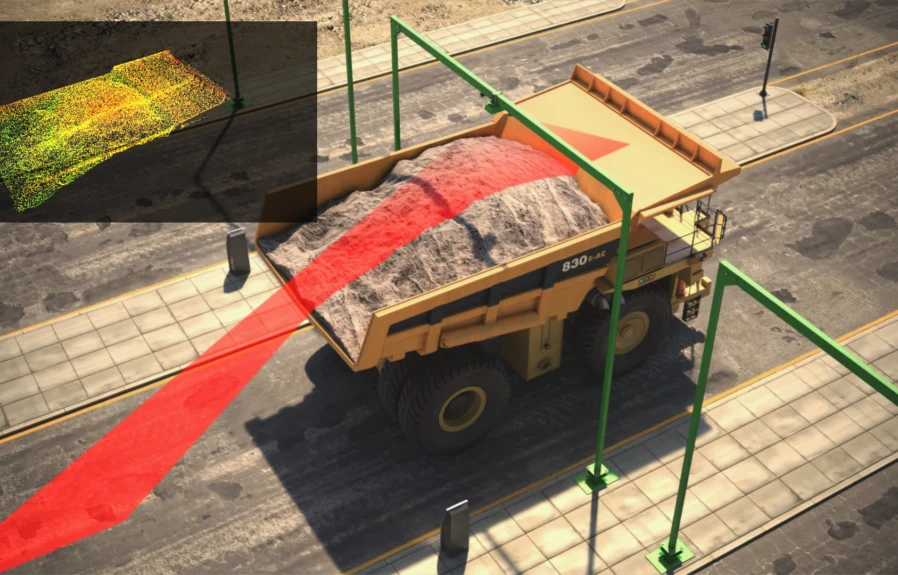

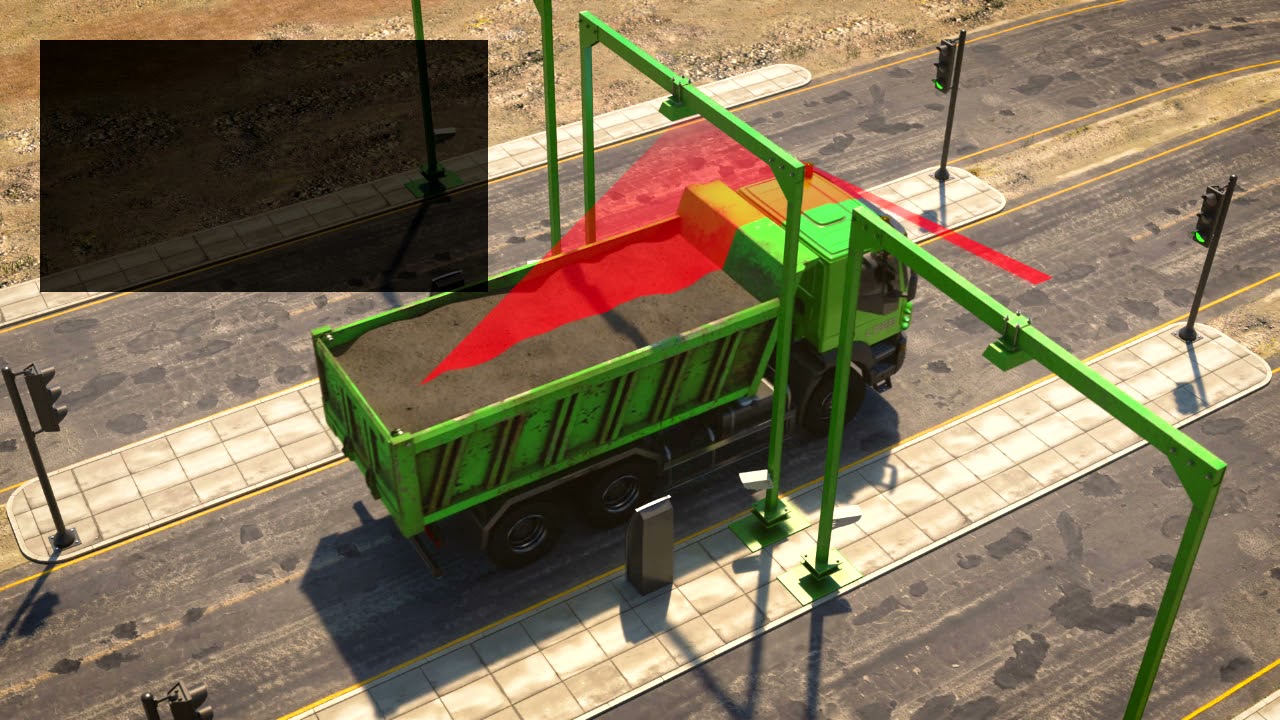

LaseTVM: Truck Volume Measurement

The LaseTVM system uses non-contact laser scanning to accurately measure bulk material volumes transported by trucks, whether stationary or in motion. By comparing 3D scans of empty and loaded vehicles, it calculates hauled volumes with about 98 % accuracy. Built for harsh industrial and mining environments, it integrates easily with automation tools and improves haulage monitoring, planning, and operational efficiency without interrupting operations.

LaseBVC: Bulk Volume Conveyor

The LaseBVC system is a non-contact laser solution designed to continuously measure bulk material volumes on conveyor belts in mining and processing operations. Using a 2D laser scanner, it captures the material profile on the moving belt and compares it with an empty-belt reference to calculate volume in real time. Built for heavy-duty industrial environments, LaseBVC improves throughput verification, process automation, and overall material handling accuracy.

LaseCAU-ML: Collision Avoidance for (Un)loaders with Multi-Layer Scanner

LaseCAU-ML is a cutting-edge collision avoidance system designed for continuous ship loading and unloading processes involving (un)loaders with vertical beams. During these procedures, accidents between the (un)loader’s vertical beam and the vessel’s hatch covers are common, resulting in significant damage, costly delays, and downtime. LaseCAU-ML uses four perfectly placed 3D multi-layer laser scanners to detect common and complex hatch cover configurations, including folded and sliding varieties, and provides real-time information to prevent critical collisions.

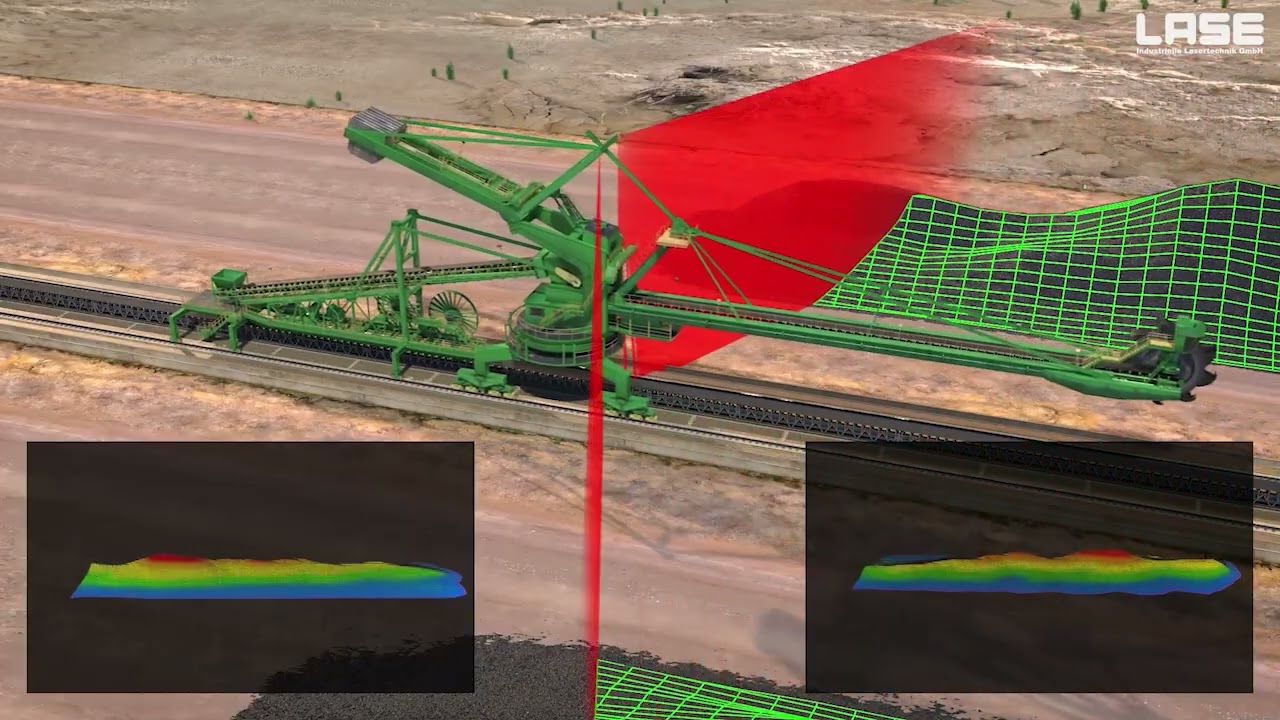

LaseBVH: Bulk Volume Heap

The LaseBVH – Bulk Volume Heap measuring system is a high-precision three-dimensional laser measuring device built specifically for volume measurements of bulk material heaps. Measurements are acquired from stackers and/or reclaimers operating in the mining area or stockpiles.