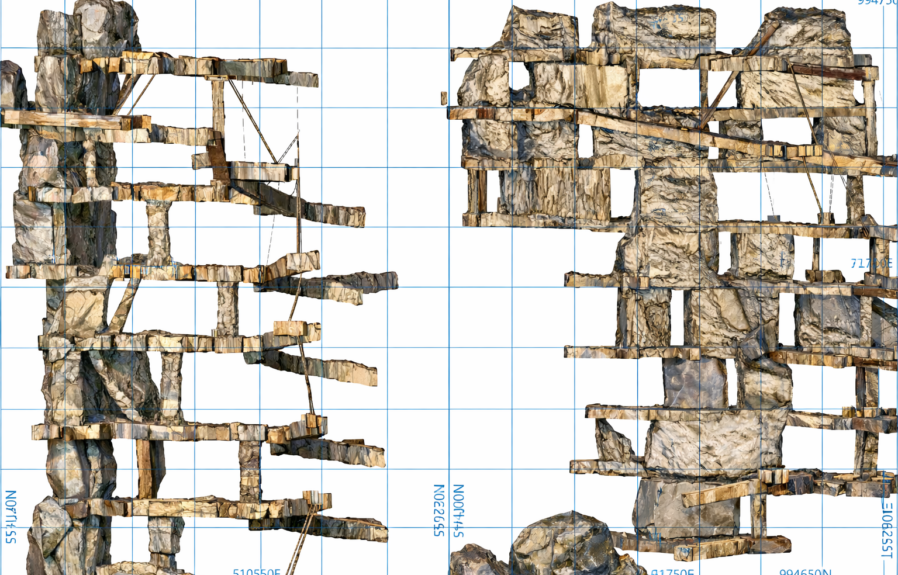

Long-hole open stoping is one of the most widely used underground mining methods in competent rock and steeply dipping orebodies.

The concept is simple. The engineering is not.

It lives in sequencing, stability management, and fill strategy.

Quick terminology

- Long-hole: production drilling with long blastholes

- Stoping: excavating large chambers within the orebody

- Open: the stope remains unsupported for a defined period

Typical mining cycle

- Drill long holes into the ore face

- Charge and blast

- Muck broken ore with an LHD from the level below

- Once mined out, either:

- Leave a pillar and advance, or

- Backfill the stope, allow curing, then mine the adjacent stope

That last step isn’t operational housekeeping.

It’s a design decision that controls local stability, dilution risk, and extraction efficiency.

Why Cemented Paste Backfill (CPB) matters

- Achieves required strength at lower binder content than many hydraulic fills

- Better water retention with reduced segregation

- Converts tailings into a structural mine material, easing surface storage pressure

- Improves stope wall confinement and overall stability

- Enables higher recovery through more aggressive sequencing when cure time is properly controlled

At your operation, which factor dominates your fill design decisions: geometry, ground conditions, binder cost, plant throughput, reschedule risk (rock burst, squeezing ground, wedge failure, etc.) or the production pressure imposed by cure time?

#backfilling #stopestability #geotechnicalengineering