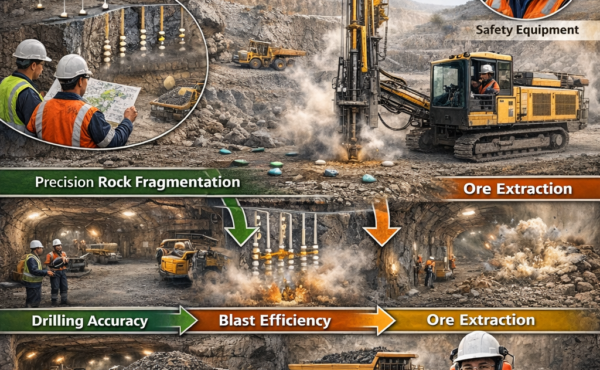

In modern mining, the production driller serves as the architect of the primary extraction phase. While the industry is increasingly moving toward automation, the role remains indispensable for ensuring the economic viability, safety, and operational efficiency of a mine. Production drilling is not merely about creating voids in rock; it is a high-precision task that dictates the success of every subsequent stage in the mining cycle, from blasting to final processing.

Job description

A production driller should be able to:

- Move, set up and operate drilling rigs and related equipment above or underground to drill holes for blasting and mineral excavation;

- Use a variety of drills and hammers including hydraulic drills, rotary, in-the-hole, and top hammer, diamond drills and other drilling machines;

- Prepare the drill site, move and set up drill following site plans and layouts, position drills and set angles and depths;

- Start and stop drills, and coordinate with other workers on the site;

- Conduct pre-operational checks and monitor conditions by checking water flow, components, fluid levels, fittings, safety equipment, as well as depths and alignments of boring positions;

- Regulate air pressure, rotary speed, and downward pressure, according to the type of rock being drilled;

- Operate secondary equipment, such as pumps and equipment used to prevent and correct problems or make minor repairs and refuel, inspect, lubricate and replace components to maintain drill;

- Meet all drill production targets without dam aging the drill;

- Read and maintain daily drill report and drilling logbook and report issues to Supervisor;

- Collaborate closely with mechanics, the production team and supervise Driller Helpers and Mine Helpers.

We need production drillers because they bridge the gap between geological planning and physical extraction. Their expertise ensures that rock is broken safely and efficiently, providing a “feed” that the rest of the mine can process profitably. As mining moves toward more complex deposits and deeper underground environments, the driller’s ability to navigate geological uncertainties remains the backbone of sustainable mining.