Every tunnelling project teaches you one thing fast: the ground always gets a vote. You can plan the cycle perfectly, but once you hit wet, fractured, or high-stress rock, the entire rhythm changes.

Water can slow a tunnel more than any mechanical delay. It weakens energy transfer, makes blasts inconsistent, and forces crews into constant adjustments.

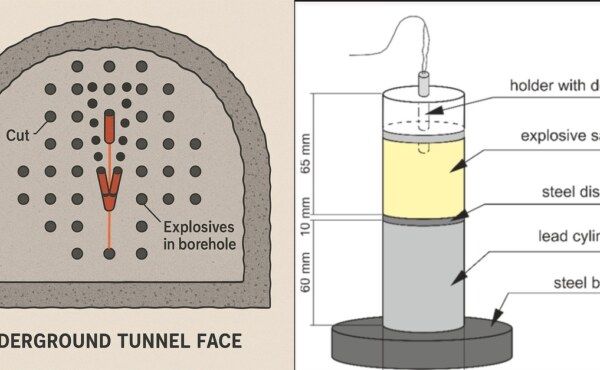

That’s why water-resistant emulsion explosives matter. Their nitrate-and-oil structure, stabilized by an emulsifier, stays intact even in saturated faces. In the field, I’ve seen this make the difference between fighting every round and keeping a steady advance.

That stability keeps fragmentation predictable, advance rates consistent, and ground support aligned with the design instead of reacting to surprises.

It’s a reminder that underground development isn’t just breaking rock. It’s understanding the ground, managing energy, and choosing tools built for the conditions. When Geotech, Blasting, and Chemistry work together, we get safer, more resilient mines and cycles crews can trust.

#undergroundmining #geotechnicalengineering #miningengineering #civilengineering #emulsionexplosives #groundstability #Blasting