In industrial mining and construction, haul roads are the vital arteries of production. However, because they are subjected to extreme axle loads and constant traffic, they are prone to structural and functional failures. When a road fails, rolling resistance increases, fuel consumption spikes, and cycle times slow down.

The most common haul road failures are rutting, potholes, and corrugation. Understanding their causes is the first step toward a cost-effective maintenance strategy.

Rutting: structural distress

Rutting is the formation of longitudinal depressions in the wheel paths. It is typically a sign of structural weakness rather than just surface wear.

- Causes: rutting often occurs when the road’s sub-grade or base layers lack the bearing capacity to support heavy haul trucks. It can also be caused by inadequate compaction during construction or the use of materials with high plastic fines that deform under pressure.

- Prevention: sub-grade stabilization: Use geotextiles or chemical stabilizers to strengthen the foundation.

- Proper layering: ensure the base and sub-base layers are of sufficient thickness and material quality (e.g., crushed stone) to distribute loads effectively.

- Compaction control: using rollers at optimal speeds (3 – 5 km/h) ensures consistent density across all lifts.

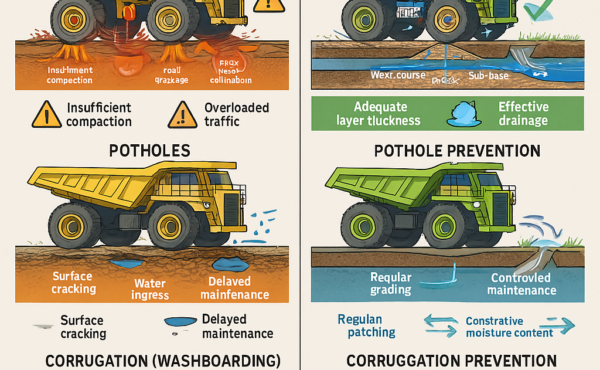

Potholes: the result of water ingress

Potholes are bowl-shaped cavities in the road surface. They are one of the most disruptive failures, often leading to immediate tire damage and mechanical strain.

- Causes: the primary driver of potholes is water. When water collects in small surface cracks or depressions, it seeps into the base material. Traffic then forces this water deeper, weakening the bond between particles and “pumping” out fines, leaving a hole behind.

- Prevention:

- Effective drainage: the road must have a “crown” (typically a 2% – 4% cross-fall) to shed water into side ditches.

- Surface sealing: applying bitumen emulsions or specialized road binders creates a water-impermeable seal, preventing moisture from reaching the sub-structure.

- Prompt patching: filling small surface defects before they expand can prevent a minor crack from becoming a major pothole.

Corrugation: the “washboard” effect

Corrugation consists of a series of transverse ripples or waves across the road surface, spaced at regular intervals.

- Causes: This often occurs on unsealed roads with granular materials that have low plasticity or a lack of “fines” to bind the larger rocks. High-speed traffic and heavy braking accelerate the shifting of these loose particles into ridges.

- Prevention:

- Material Selection: Use a well-graded wearing course material that has a balanced mix of coarse aggregate and binding fines.

- Dust Suppression: Chemical binders (like lignosulphonates or polymers) help glue the surface particles together, making them resistant to shifting.

- Speed Enforcement: Reducing vehicle speed decreases the vibration frequency that triggers the formation of washboards.

Integrated maintenance strategies

Preventing these failures is significantly cheaper than repairing them. A “Good roads, more loads” philosophy relies on three pillars:

- Routine Grading: using motor graders to maintain the road’s profile and remove windrows that trap water.

- Water Management: ensuring culverts and ditches are clear of debris to prevent saturation of the road base.

- Operator Training: educating truck drivers to avoid “tramlining” (driving in the exact same tracks) and to report road defects early.

By combining robust initial design with proactive surface management, operators can reduce maintenance OPEX by up to 30% and significantly extend the life of their haulage fleet.