In the heavy industries of mining and civil construction, haul roads are the arteries of production. However, traditional road management—often based on static designs and reactive maintenance—frequently leads to excessive fuel consumption, vehicle wear, and safety risks. Today, a trifecta of digital tools, truck telemetry, and Artificial Intelligence (AI) is transforming these roads from passive infrastructure into optimized, data-driven assets. Let’s explore the impact of each tool.

Precision design via digital twins

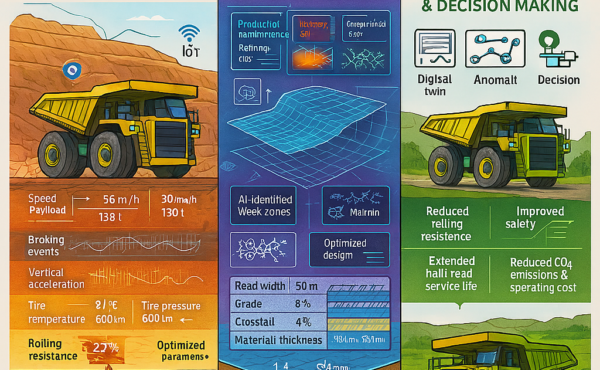

The optimization process begins long before a truck hits the dirt. Engineers now use specialized Haul Road Design Software and Digital Twins to create high-fidelity virtual replicas of the site.

By integrating drone-captured photogrammetry and LiDAR data, AI algorithms can automatically detect optimal route geometry. These digital tools analyze:

- Grade and slope: AI identifies sections where the gradient is too steep, which can lead to excessive engine strain and fuel burn [1].

- Cross-falls and drainage: digital models simulate water runoff to prevent “washouts” and mud accumulation, which significantly increase rolling resistance [1].

- Berm compliance: safety-focused AI tools (such as Strayos) automatically measure berm heights against regulatory standards (e.g., MSHA) to ensure they are at least mid-axle height for the largest vehicles on site [1].

Real-time insights through truck telemetry

Once the road is operational, truck telemetry provides a continuous feedback loop. Modern heavy haulers are equipped with sensors that measure “rack” (lateral frame twisting), “pitch” (front-to-back force), and suspension strut pressure at frequencies of up to 10 times per second.

Systems like Caterpillar’s Road Analysis Control (RAC) use this telemetry to identify “hotspots”—potholes, ruts, or washboard surfaces—that are invisible to a static map. When a truck hits a defect, the telemetry system tags the exact GPS coordinates. This shifts maintenance from an arbitrary schedule to a targeted, surgical approach, where graders are dispatched only to the specific road segments requiring repair.

AI-driven performance optimization

AI acts as the “brain” that synthesizes design data and telemetry into actionable intelligence. Two critical areas of AI impact include:

Fuel and rolling resistance modeling

Fuel is often the largest variable cost in hauling. AI models, specifically Artificial Neural Networks (ANN), are used to calculate the relationship between road roughness (measured by the International Roughness Index or IRI) and fuel consumption. Research has shown that upgrading a road from “poor” to “moderate” quality using AI-informed maintenance can reduce fuel costs by 3% to 5% per cycle.

Predictive maintenance and safety

AI doesn’t just report current conditions; it predicts future failures. By analyzing historical telemetry data, AI can forecast when a specific road segment will deteriorate based on traffic volume and weather patterns [2].

Key insight: AI-based traffic management systems can dynamically adjust speed limits or reroute traffic in real-time if a road segment becomes hazardous, reducing accidents related to driver fatigue or poor road conditions by up to 80%.

Conclusion

The true power of these technologies lies in their integration. A digital tool designs the road; telemetry monitors its health in real-time; and AI optimizes the maintenance schedule to ensure peak performance. This ecosystem results in faster cycle times, lower tire and component wear, and a significantly reduced carbon footprint.

References

[1] “Product Spotlight: Haul Road AI.” Accessed: Jan. 22, 2026. [Online]. Available: https://blog.strayos.com/product-spotlight-haul-road-ai/

[2] Y. ADEOYE, E. Onotole, T. OGUNYANKINNU, G. Aipoh, A. OSUNKANMIBI, and J. Egbemhenghe, “Artificial Intelligence in Logistics and Distribution: The function of AI in dynamic route planning for transportation, including self-driving trucks and drone delivery systems,” World Journal of Advanced Research and Reviews, vol. 25, pp. 155–167, Feb. 2025, doi: 10.30574/wjarr.2025.25.2.0214.