In-Pit Crushing and Conveying (IPCC) systems represent a significant evolution in open-pit mining, designed to reduce or replace traditional truck haulage by integrating crushing stations and conveyor belts directly within the mine pit (Oberrauner & Turnbull, 2024).

This innovative approach offers substantial benefits, including reduced operational expenditure, enhanced safety by minimizing mobile vehicle traffic, and considerable environmental improvements such as decreased greenhouse gas emissions (up to 25% CO2), noise, and dust (TAKRAF, n.d.).

IPCC also leads to a notable reduction in manpower requirements (40-60%) and lower maintenance needs (AlHabib, 2023).

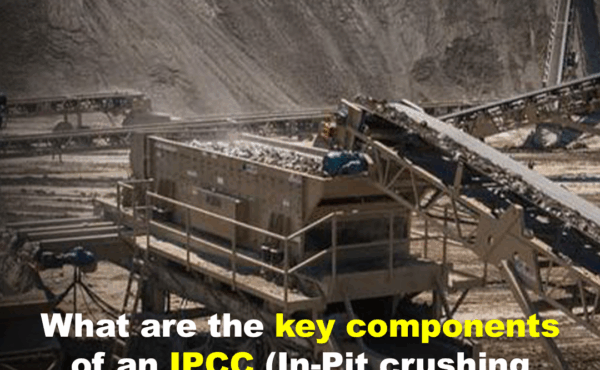

Key components include crushing stations such as gyratory, jaw, impact, sizers, and roll crushers which are crucial for reducing material to a conveyable size.

Conveying systems, the backbone of continuous material transport, encompass various conveyor types (e.g., fixed, shiftable, steep-incline) and essential auxiliary components like idlers, pulleys, and transfer stations (Carmaky, 2024).

Supporting infrastructure is vital, including robust electrical systems with transformers and mobile substations, enabling the predominantly electric-powered IPCC operations (ZeusBTC, n.d.).

While IPCC systems demand a higher initial capital investment and present challenges related to system flexibility and specialized maintenance, their long-term operational savings and sustainability benefits position them as a transformative solution for large-scale, long-life mines (AlHabib, 2023).

What part of an IPCC system do you think is most important for keeping material moving smoothly? Share your thoughts!